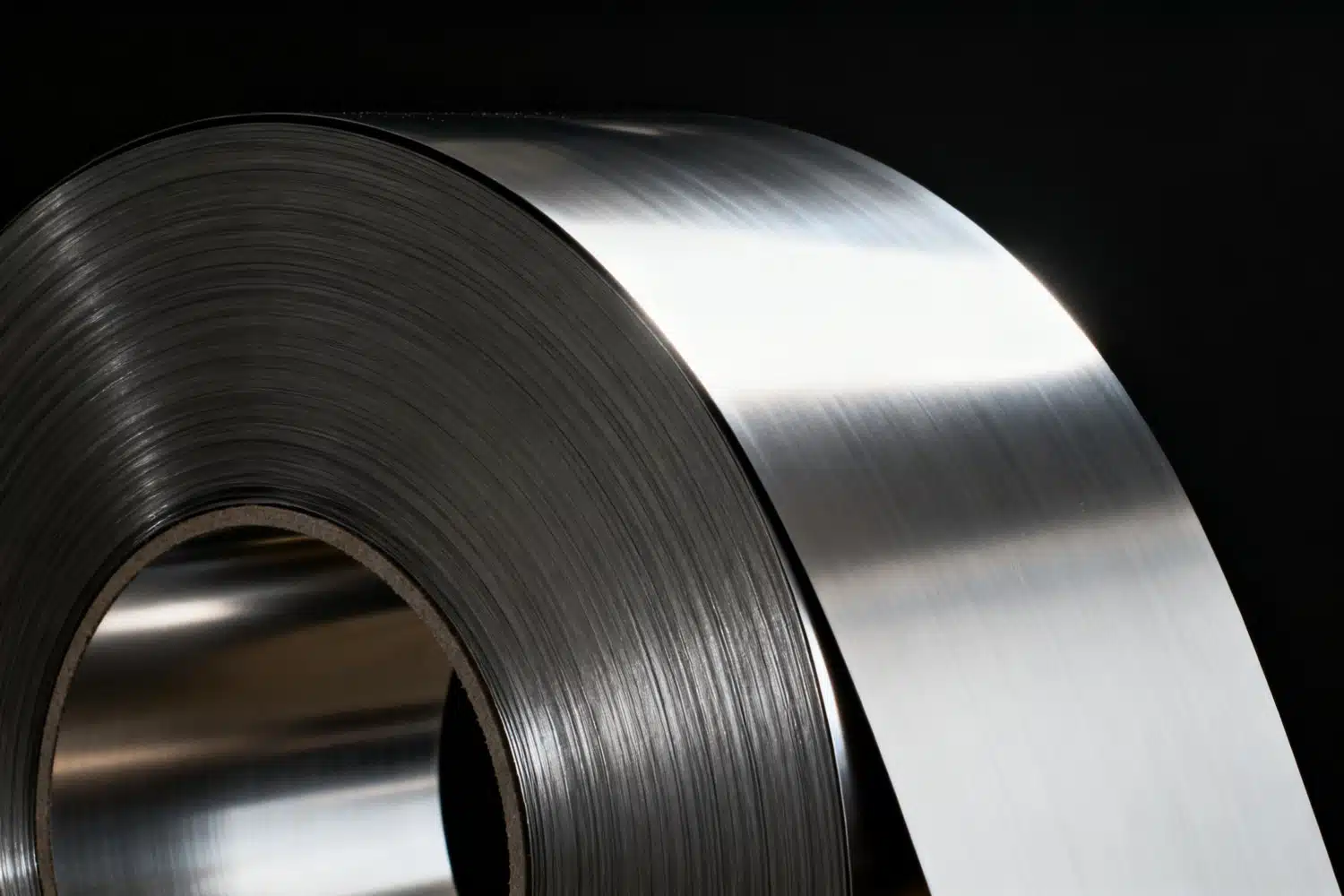

Choosing the right precision stainless steel strip is critical for product performance, cost efficiency, and longevity. Among the 300 series austenitic steels, 301, 304, and 316L are the most widely used—but their differences in composition, properties, and applications are often misunderstood. This guide breaks down these grades to help you make an informed decision.

Chemical Composition: The Foundation of Performance

Each grade’s properties stem from its unique alloy composition, which determines corrosion resistance, strength, and workability.

- 301 Stainless Steel: Contains 16–18% chromiumand 6–8% nickel. Its lower nickel content (compared to 304) enables work hardening—cold rolling or forming significantly increases its strength and hardness . This makes it ideal for applications requiring high tensile strength after fabrication.

- 304 Stainless Steel: The industry benchmark, with 18–20% chromiumand 8–10.5% nickel.This balanced composition provides excellent corrosion resistance in most environments, along with superior formability and weldability. It is non-magnetic when annealed and exhibits good performance from cryogenic temperatures up to 800°C.

- 316L Stainless Steel: Distinguishes itself with the addition of 2–3% molybdenum, enhancing resistance to chlorides and acidic environments.Its low carbon content (≤0.03%) minimizes carbide precipitation during welding, making it suitable for harsh conditions.

Mechanical Properties: Strength vs. Flexibility

The optimal choice depends on whether your priority is strength, corrosion resistance, or a balance of both.

Property | 301 | 304 | 316l |

Tensile Strength | 520–1,500 MPa | ≥520 MPa | 530–1,160 MPa |

Yield Strength | ≥205 MPa | ≥205 MPa | ≥200 MPa |

Key Trait | High work-hardening rate | Balanced strength & ductility | Superior corrosion resistance |

- 301: Excels in high-strength applicationslike springs, fasteners, and structural components . Its ability to gain strength through cold forming allows manufacturers to achieve precise hardness levels (e.g., 1/4 Hard, 1/2 Hard, Full Hard).

- 304: Offers reliable all-around performance for everyday corrosive environments (e.g., moisture, mild chemicals) . It maintains good ductility (≥40% elongation) for deep drawing, bending, and welding.

- 316L: Prioritizes corrosion resistancein aggressive media (e.g., seawater, acids) . Its higher nickel content (10–14%) also improves toughness at low temperatures.

3. Corrosion Resistance: Matching the Environment

The operating environment dictates which grade to use:

- 301: Suitable for mild or indoor environments(e.g., dry atmospheric conditions) . It resists rust under normal conditions but is not recommended for prolonged exposure to chemicals, salts, or humidity

- 304: Provides excellent resistance to organic acids, freshwater, and atmospheric exposure. It is widely used in food processing, kitchen equipment, and architectural trim . However, it is vulnerable to chloride-induced pitting in coastal or industrial areas

- 316L: The top choice for harsh environmentscontaining chlorides, acids, or high temperatures . Its molybdenum content resists pitting and crevice corrosion, making it essential for Marine equipment, Pharmaceutical and chemical processing, Coastal architecture

4. Application Scenarios: Which Grade for Your Project?

Choose 301 for:

- Springs, clamps, and high-strength mechanical parts

- Automotive components (e.g., seatbelt springs, exhaust systems)

- Applications where cold working can enhance strength

Choose 304 for:

- Food and beverage equipment (sinks, tanks, processing machinery)

- Architectural trim, railings, and HVAC components

- General industrial parts requiring a balance of corrosion resistance and formability

Choose 316L for:

- Marine hardware, desalination plants, and boat fittings

- Medical implants and pharmaceutical tubing

- Chemical tanks, valves, and pipelines handling corrosive fluids

5. Cost Considerations: Balancing Performance and Budget

While 316L offers the highest corrosion resistance, it is ~50–80% more expensive than 304due to its molybdenum and nickel content . 301 is often the most cost-effective for high-strength needs but may require protective coatings in corrosive environments. For most non-extreme applications, 304 provides the best value.

Conclusion: Making the Right Choice

- Opt for 301 when you need high strength and hardness achievable through cold working, and the environment is not highly corrosive.

- Select 304 for general-purpose usewhere corrosion resistance, formability, and cost-effectiveness are prioritized.

- Choose 316L for aggressive environmentscontaining chlorides, acids, or high temperatures, particularly in medical, marine, or chemical applications.

By aligning your project’s mechanical, environmental, and budgetary requirements with these grades’ properties, you can ensure optimal performance and durability.