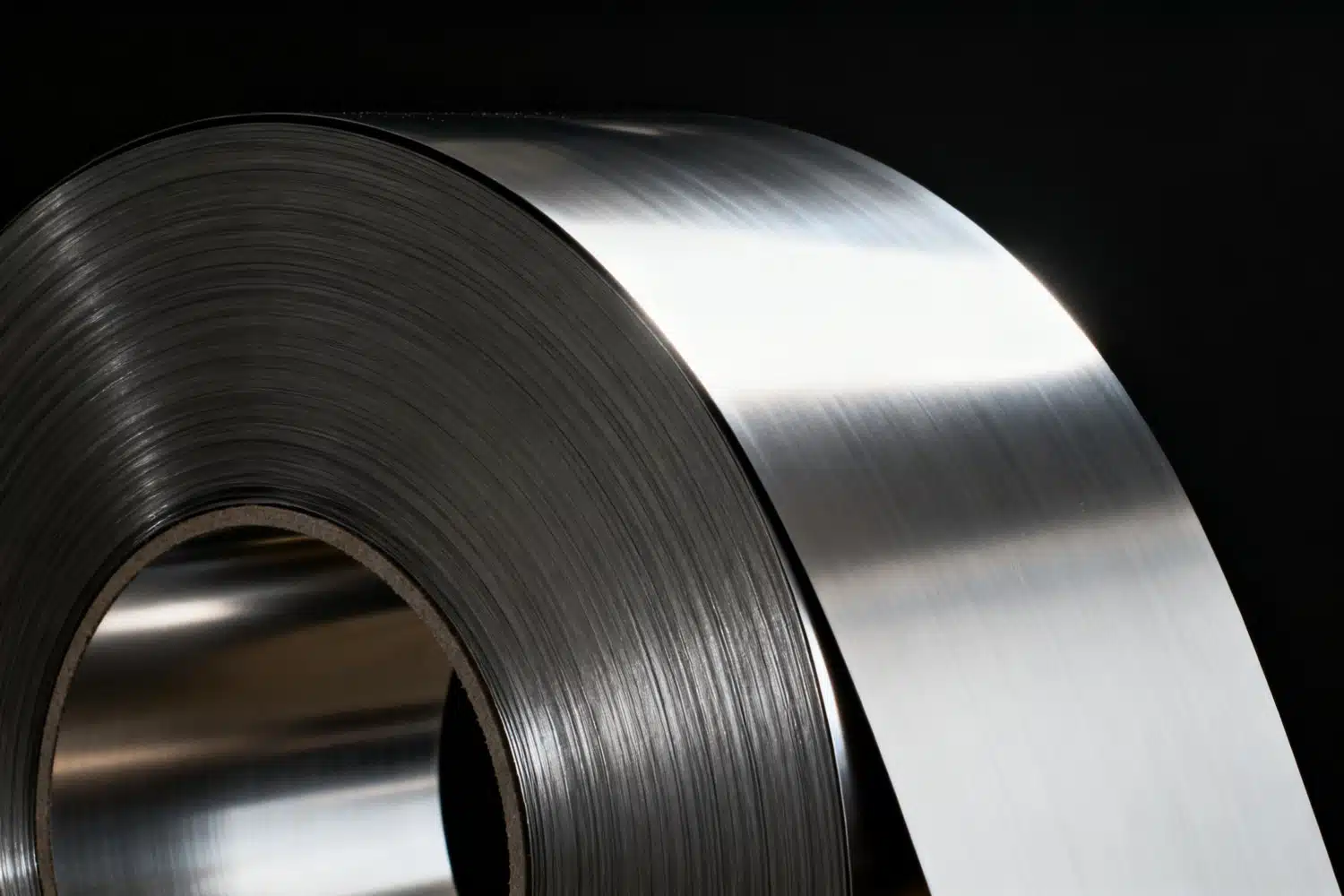

In the world of industrial materials, 301 full hard stainless steel stands out as a high-performance material with exceptional properties. This blog post will explore the characteristics, advantages, applications, and proper usage of 301 full hard stainless steel, helping you gain a comprehensive understanding of this remarkable material.

What is 301 Full Hard Stainless Steel?

301 full hard stainless steel is an austenitic stainless steel alloy that undergoes special cold-working processes to achieve maximum tensile and yield strength with minimal elongation. It contains 16 – 18% chromium and 6 – 8% nickel, giving it excellent corrosion resistance and mechanical properties. Its high strength and hardness make it suitable for applications requiring high strength and dimensional stability.

Outstanding Properties

High Strength and Hardness

With a minimum tensile strength of 1276 MPa and yield strength of 965 MPa, 301 full hard stainless steel can withstand high stress and heavy loads. This makes it ideal for springs, fasteners, and other components in the automotive and machinery industries.

Property Minimum Value:

- Tensile Strength: 1276 MPa

- Yield Strength: 965 MPa

Good Corrosion Resistance

The chromium and nickel content in 301 full hard stainless steel allows it to form a protective chromium oxide layer in various environments. This resists atmospheric and water corrosion and performs well in mild corrosive environments like urban and industrial settings.

Precision Dimensions

Advanced cold – rolling technology ensures high precision in thickness and width dimensions. Thickness can be as thin as 0.01mm, meeting strict manufacturing tolerances and ensuring interchangeability and assembly accuracy.

Applications Across Industries

Automotive Industry

301 full hard stainless steel is widely used in automotive seat belt springs, suspension springs, and brake springs. Its high strength and corrosion resistance ensure vehicle safety and reliability under complex driving conditions.

Electronics Industry

In the electronics sector, it’s used for components like springs and brackets in electronic devices. Its high strength and dimensional stability ensure good electrical contact and structural support, meeting the miniaturization and high-performance requirements of electronic products.

Machinery Manufacturing

It’s suitable for various mechanical components such as pressure springs and torsion springs. It provides strong elastic force and durability, ensuring smooth equipment operation.

Construction and Infrastructure

In construction, it’s used for architectural components and fasteners. Its corrosion resistance ensures long – term reliability in construction projects.

Proper Use and Maintenance

Storage

Store 301 full hard stainless steel in a dry, ventilated warehouse, away from corrosive substances. Place it on pallets to avoid direct contact with the ground and prevent moisture and contamination.

Processing

When processing, select appropriate tools and processes based on its high strength and hardness. For example, use specialized cutting tools and set proper cutting parameters to avoid tool wear and processing defects.

Maintenance

Regularly inspect and maintain products made from 301 full hard stainless steel. Clean them to remove surface dirt and corrosive substances, and promptly address any issues found to extend product life.

How to Choose a Reliable Supplier?

When selecting a 301 full hard stainless steel supplier, consider the following:

- Quality Certification: Choose suppliers with ISO9001 and ISO14001 certifications to ensure product quality and stability.

- Product Range: Select suppliers offering a wide range of product specifications and grades to meet diverse needs.

- Customization Service: Pick suppliers providing comprehensive customization services to satisfy specific application requirements.

- After-Sales Support: Opt for suppliers with good after-sales support to promptly address quality issues and provide solutions.

Conclusion

301 full hard stainless steel is a high-performance material with high strength, good corrosion resistance, and precision dimensions. It’s widely used in automotive, electronics, machinery, and construction industries. Proper use and maintenance can extend its service life and ensure optimal performance. When choosing a supplier, consider factors like quality certification, product range, customization services, and after-sales support to ensure reliable material supply and quality assurance.

By understanding the properties and applications of 301 full hard stainless steel, you can better utilize its advantages in your projects and benefit from its excellent performance.