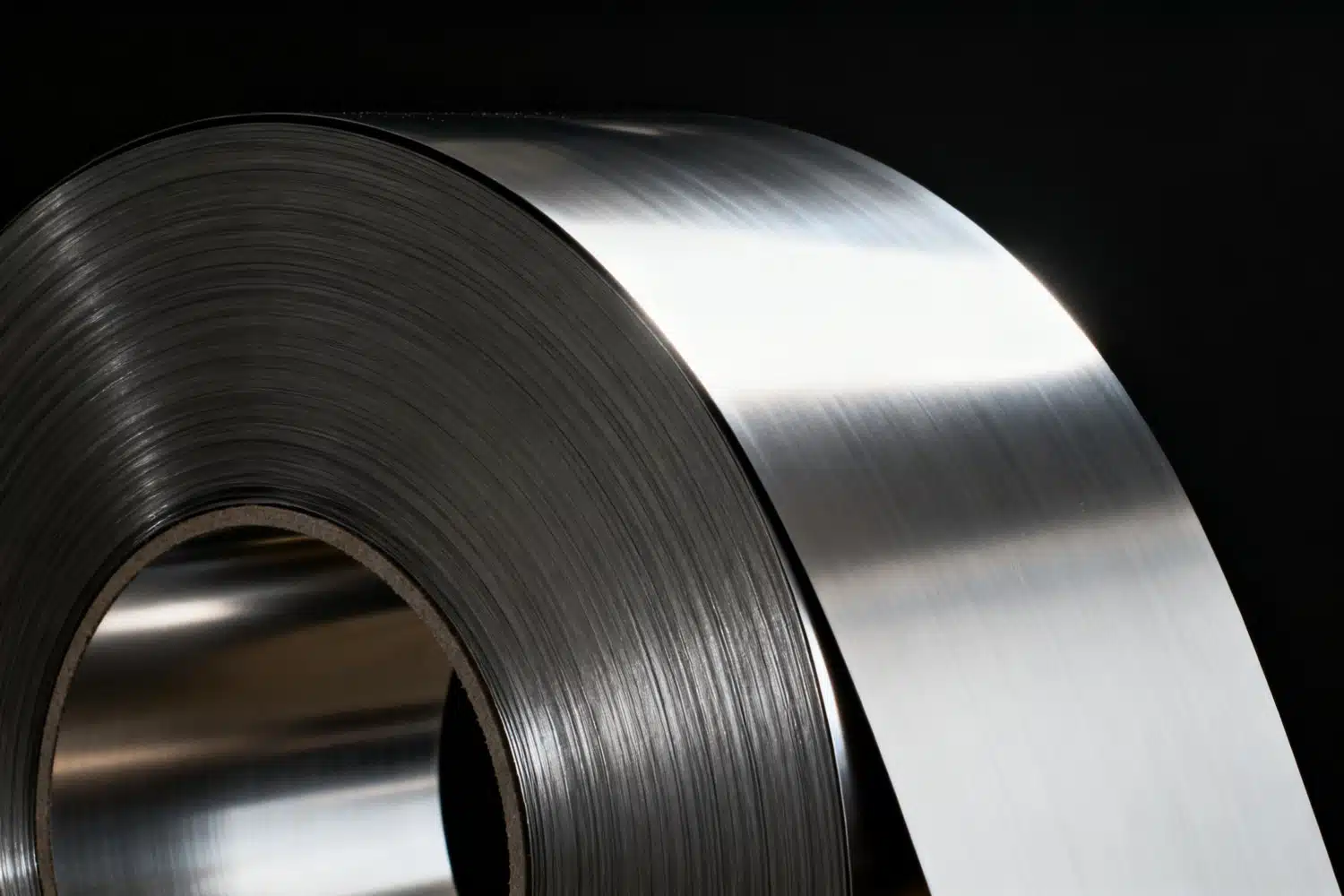

Stainless steel’s versatility stems not only from its alloy composition but also from its varied mechanical processing states. Among cold-worked stainless steels, the 3/4 Hard (3/4H) and Full Hard (H) tempers represent critical points on the strength-ductility spectrum. While both are produced through cold reduction processes, their divergent mechanical properties and microstructures lead to distinctly different engineering applications and limitations. Understanding these differences is essential for material selection in demanding industrial environments.

The Science of Cold Work Hardening

To grasp the divergence between 3/4H and H states, we must first examine the metallurgical transformations induced by cold working. Stainless steels, particularly austenitic grades like 304 and 316, cannot be hardened by heat treatment. Instead, cold mechanical deformation—such as rolling, drawing, or bending—introduces permanent microstructural changes.

As the steel is plastically deformed:

- Dislocation density multiplies dramatically within the crystal lattice

- Slip planes and grain boundaries become clogged with these linear defects

- Lattice distortion (point defects and strain fields) intensifies with increasing deformation.

This microstructural chaos directly translates to macroscopic property shifts:

- Strength and hardness rise due to dislocation entanglement, which impedes further dislocation motion

- Ductility and toughness plummet as the material loses its capacity for additional plastic flow

- Residual stresses accumulate, particularly near grain boundaries, raising susceptibility to stress corrosion cracking (SCC)

The extent of these changes is quantified by the percentage of cold reduction, which dictates the final temper designation—whether 1/4 Hard, 1/2 Hard, 3/4 Hard, or Full Hard.

3/4 Hard vs. Full Hard: A Property Comparison

Data for SUS304 stainless steel (a Japanese standard analogous to AISI 304) reveals stark contrasts between these tempers

Property | 3/4 Hard | Full Hard |

|---|---|---|

Hardness (HV) | 310–360 | 370–420 |

Yield Strength (MPa) | ≥665 | ≥880 |

Tensile Strength (MPa) | 930–1,120 | 1,130–1,300 |

Elongation at Break (%) | ~3% |

1. Strength and Hardness: The Trade-Off for Robustness

3/4 Hard: Offers a substantial strength upgrade over annealed (soft) stainless steel—nearly tripling the yield strength (from ~205 MPa to 665 MPa)—while retaining minimal ductility for slight forming operations. This temper resists moderate impacts and sustains structural loads in applications like fastener plates or conveyor components.

Full Hard: Pushes strength near the material’s theoretical limits. With tensile strength soaring to 1,300 MPa, H3 approaches the strength of some low-carbon martensitic steels. However, this comes at the cost of extreme brittleness. Like glass, it fractures with minimal warning when overloaded or bent, limiting its use to strictly static, non-forming applications.

2. Ductility and Formability: From Limited to Nonexistent

3/4 Hard: Retains approximately 3% elongation, permitting very limited bending or flattening operations post-rolling. For example, it can withstand minor adjustments during installation but will crack if bent sharply. This makes it suitable for pre-formed parts like shims or stamped brackets requiring moderate contours.

Full Hard: Effectively loses all formability with elongation plunging to 1%. Any attempt to bend, stretch, or stamp FH material risks immediate fracture. It is essentially a “finished shape” product, used as-rolled for flat components like industrial blades or wear plates.

3. Residual Stress and Corrosion Vulnerability

Both tempers accumulate internal stresses, but FH’s severe deformation makes it particularly prone to:

Stress Corrosion Cracking (SCC): Chlorides (even at low concentrations) can trigger catastrophic intergranular cracks in highly stressed regions.

Season Cracking: Spontaneous failure may occur over time in corrosive atmospheres due to residual tensile stresses, especially in thinner gauges.

Mitigation: Intermediate annealing is mandatory during multi-stage forming of 3/4H material. For FH, stress-relief annealing may be required post-rolling if environmental exposure is anticipated.

4. Microstructural Evolution: Dislocation Density Matters

Cold work hardening progresses non-linearly:

At 3/4 Hard, dislocation cells and tangles are dense but still permit minor plastic flow under high stress.

At Full Hard, the microstructure approaches saturation dislocation density, with cell walls evolving into sharp subgrain boundaries. This severely limits further deformation capacity and increases notch sensitivity.

Applications: Where Each Temper Excels

The choice between 3/4H and FH hinges entirely on functional demands:

3/4 Hard (3/4H) Applications:

- Springs and Clips: Requires moderate elasticity and fatigue resistance (e.g., automotive suspension components).

- Structural Brackets: Where strength outweighs formability needs, such as HVAC mounting hardware.

- Partially Formed Components: Stamped housings or guard plates needing minimal bends.

Full Hard (FH) Applications:

- Industrial Blades and Cutting Edges: For paper, textile, or food processing machinery demanding extreme wear resistance.

- Armor Components: Lightweight ballistic or fragmentation layers where hardness defeats penetration.

- Shims and Precision Grinding Stock: Flat, dimensionally stable parts machined by grinding, not bending.

Selection Guidelines: Navigating the Trade-Offs

Choose 3/4 Hard when:

✅ Moderate post-forming (bending <90°) is required.

✅ The part faces dynamic loads or cyclic stresses (e.g., springs).

✅ Cost-effective strength is needed without annealing.

Choose Full Hard when:

✅ Absolute maximum hardness and wear resistance are non-negotiable.

✅ The component geometry is simple and flat (no forming post-rolling).

✅ The environment is controlled (low chlorides) to mitigate SCC risks.

Conclusion: Beyond the Surface Hardness

While both 3/4 Hard and Full Hard stainless steels belong to the cold-worked family, they serve divergent engineering roles. 3/4 Hard occupies a pragmatic middle ground—boosting strength significantly while retaining a sliver of formability and toughness. Full Hard, conversely, represents the frontier of cold-work hardening, delivering unparalleled strength and abrasion resistance at the expense of functional brittleness. For designers, the decision hinges not merely on strength specifications but on a holistic view of manufacturing processes, environmental exposure, and functional demands. In high-stakes applications, specifying the optimal temper—whether 3/4H or FH—can mean the difference between resilient performance and catastrophic failure.