1. Introduction to 301 Spring Tempered Stainless Steel

301 spring tempered stainless steel represents the pinnacle of cold-work optimization in austenitic stainless steels. Designed for applications demanding exceptional fatigue resistance, high tensile strength, and imensional stability, this material achieves its properties through a specialized process chain: cold reduction (typically 50–60%) followed by low-temperature aging (300–400°C).Unlike conventional hardened states (e.g., Full Hard or Extra Hard), spring tempering balances extreme strength with controlled ductility, making it ideal for dynamic-load components like valve springs, electrical contacts, and aerospace fasteners. Its unique microstructure—dominated by strain-induced martensite and stabilized dislocation networks—enables unmatched performance in cyclic-stress environments .

2. Metallurgical Foundation: How Spring Tempering Transforms 301 SS

The superiority of spring-tempered 301 stems from two synergistic metallurgical phenomena:

2.1 Strain-Induced Martensite (SIM) Formation

During cold working, 301’s metastable austenite partially transforms to martensite. Key drivers include:

- Deformation Severity: ≥50% cold reduction generates >70% martensite, elevating yield strength to 1,400–1,500 MPa.

- Temperature Dependence: SIM accelerates below the Md₃₀ temperature (≈15°C), allowing precise control via process cooling.

2.2 Stress-Relief Aging

Post-rolling low-temperature aging (300–400°C) achieves:

- Dislocation Rearrangement: Reduces residual stresses by 40–60% without triggering recrystallization.

- Carbide Precipitation: Nano-scale M₂₃C₆ carbides pin dislocations, enhancing fatigue strength to 60–70% of UTS (vs. 40–50% in Full Hard) .

- Resultant Microstructure: High-density martensite laths with coherent precipitates, minimizing crack propagation paths under cyclic loads .

3. Mechanical Properties: Quantifying the Spring Temper Advantage

Spring-tempered 301 outperforms other tempers in critical metrics for dynamic applications:

Property | Spring Temper | Full Hard | Annealed |

|---|---|---|---|

Tensile Strength | 1,740–2200 MPa | 1,275–1,300 MPa | 515–620 MPa |

Yield Strength | 1,400–1,500 MPa | 1,100–1,200 MPa | ≥205 MPa |

Elongation |

| ≥40% | |

Fatigue Strength | 960–1,300 MPa | 510–650 MPa | 200–250 MPa |

Hardness (HV) | 550–620 | 370–430 | 140–180 |

Key Performance Drivers:

- Fatigue Resistance: Stress-relief aging eliminates micro-crack initiation sites, extending service life by 2–3× vs. non-aged cold-worked states.

- Elastic Limit: Retains 95% of deformation energy without permanent set—critical for springs requiring consistent force output.

- Creep Resistance: Stable up to 300°C, outperforming carbon-steel springs in elevated-temperature environments.

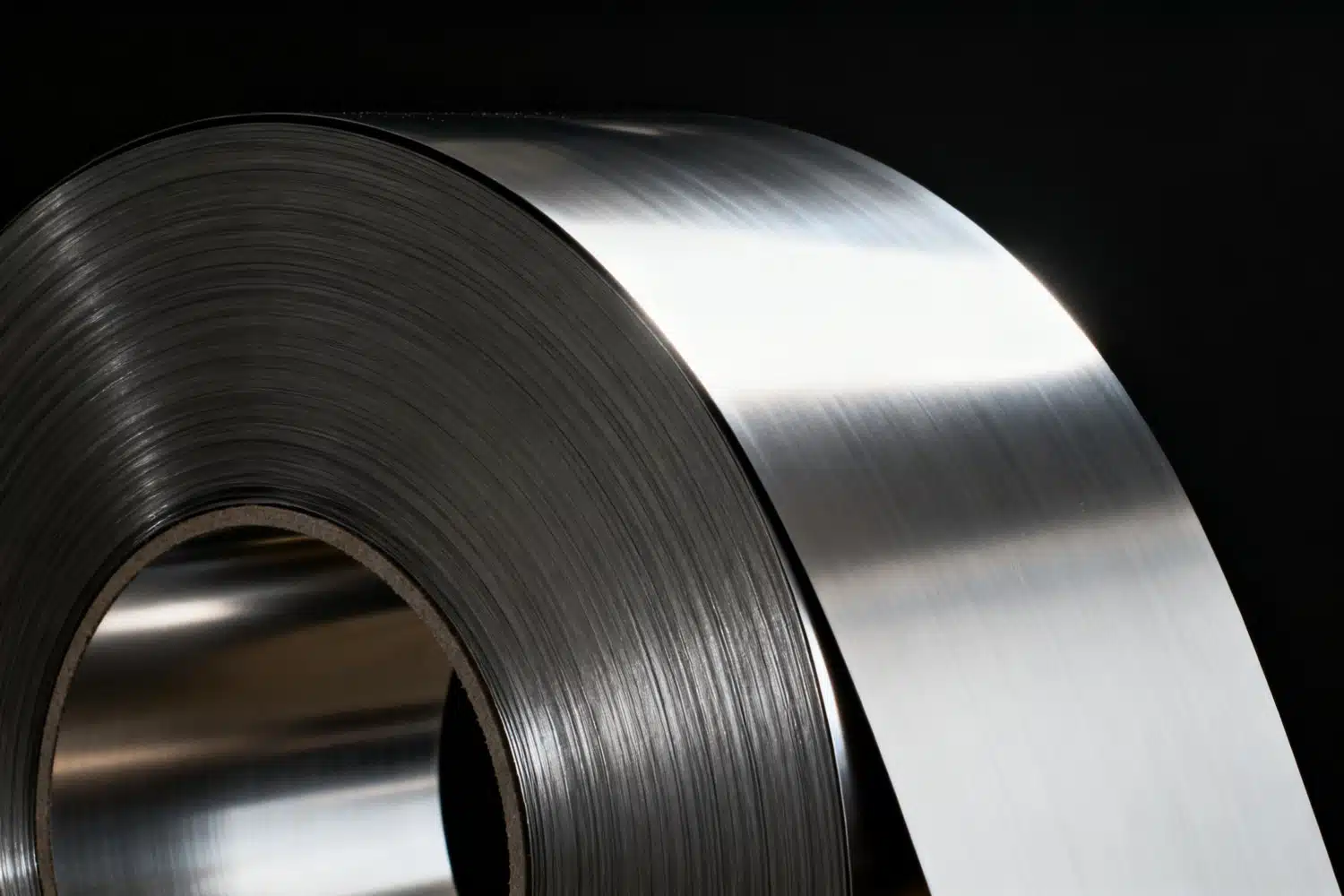

4. Processing: From Coil to Spring-Ready Strip

Manufacturing spring-tempered 301 involves precision-controlled stages:

4.1 Cold Reduction

- Rolling Passes: Sequential reductions (total 50–60%) via cluster mills to ensure uniform thickness ±0.005 mm.

- Lubrication Control: Emulsions minimize friction-induced temperature spikes that destabilize SIM formation.

4.2 Stress-Relief Aging

- Thermal Profile: 1–2 hours at 350°C ±10°C in inert atmosphere to prevent oxidation.

- Cooling Rate: Controlled slow cooling (<20°C/min) to avoid re-austenitization.

4.3 Surface Finishing

- Mirror Polishing: Reduces surface roughness (Ra <0.2 μm) to suppress fatigue-crack nucleation.

- Pickling/Passivation: Restores Cr-oxide layer compromised during rolling.

5. Design and Fabrication Guidelines

5.1 Spring Design Optimization

- Stress Distribution: Use FEA to avoid stress concentrators (e.g., sharp bends with radii <4× thickness).

- Load Cycles: For >10⁶ cycles, limit operational stress to ≤45% of UTS.

5.2 Forming and Machining

- Bending: Only feasible in annealed state; final tempering post-forming.

- Welding: Laser/TIG preferred; pre-heat to 150°C and post-weld aging mandatory to prevent HAZ embrittlement.

- Grinding: Use CBN wheels to avoid work softening.

5.3 Corrosion Management

- Limitations: Reduced Cr diffusion in high-martensite structures lowers pitting resistance (PREN ≈16 vs. 18 for annealed 304).

- Mitigations: Avoid chloride-rich environments; specify electropolishing for critical applications.

6. Applications: Where Spring Temper Excels

Spring-tempered 301 dominates in high-reliability sectors:

Industry | Components | Performance Benefit |

Aerospace | Landing gear springs, flap actuators | Weight savings (density 7.93 g/cm³) + fatigue resistance |

Automotive | Valve springs, seatbelt retractors | High cyclic load capacity (10⁷ cycles at 700 MPa) |

Medical | Surgical tool arms, implant delivery systems | Biocompatibility (per ISO 5832) + sterilization stability |

Electronics | Connector clips, MEMS contacts | Low magnetic permeability (μᵣ <1.02 after aging) |

Industrial | Pressure relief valves, conveyor belt tensioners | Abrasion resistance (HV >450) |

7. Comparison with Competing Spring Materials

301 Spring Temper vs. Alternatives:

- vs. 17-7 PH Stainless Steel: Lower cost (≈20% savings) and simpler processing (no solution annealing/conditioning), but lower UTS ceiling (1,860 vs. 2,000 MPa).

- vs. Carbon Steel Springs: Superior corrosion resistance and no coating required, though carbon steel offers higher toughness at sub-zero temperatures.

- vs. Phosphor Bronze: Higher fatigue strength (960 vs. 400 MPa) and temperature stability, but limited conductivity

8. Failure Analysis and Maintenance

Common failure modes and prevention:

Season Cracking: Residual stress + corrosive media → catastrophic SCC. Fix: Specify 301L (low-carbon variant) for welded assemblies.

Fatigue Fracture: Initiated at surface imperfections. Fix: Mandatory surface polishing + NDT inspection.

Relaxation: Permanent set under sustained load. Fix: Design stress ≤60% of yield strength.

9. Conclusion: Engineering with Precision

301 spring tempered stainless steel delivers an optimal synergy of strength, fatigue resistance, and manufacturability for dynamic-load applications. Its processing—combining severe cold work with stabilized aging—creates a microstructure resilient to cyclic deformation, outperforming conventional hardened states in lifespan-critical systems. For engineers, success hinges on:

- Designing within ductility limits (avoid bending post-tempering),

- Controlling environmental exposure (mitigating SCC risks),

- Leveraging specialized suppliers for precision processing.

When optimized, 301 spring temper enables breakthroughs in aerospace, automotive, and medical technology — where failure is not an option.