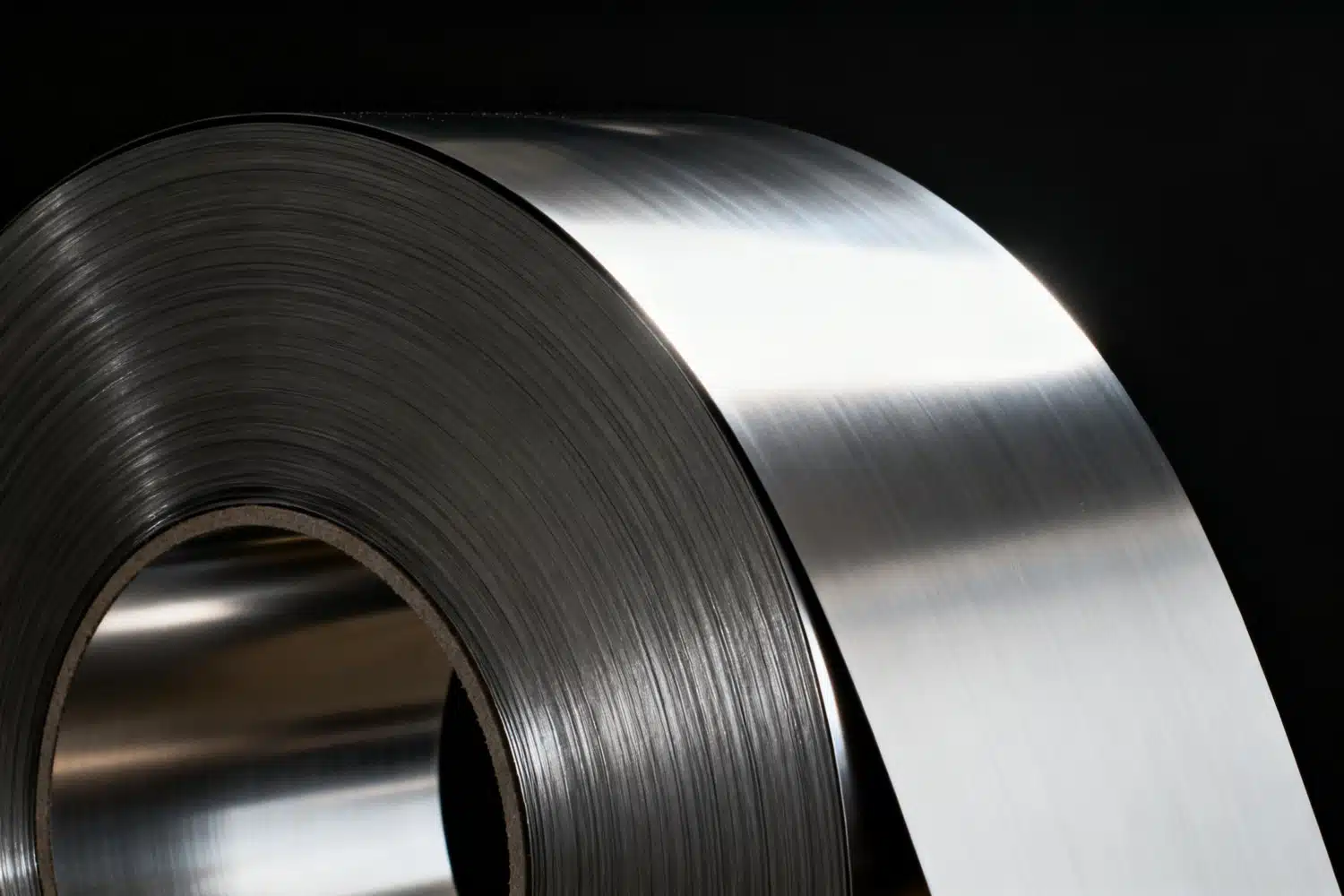

1. Introduction: The Biocompatibility Revolution

316L stainless steel (UNS S31603) represents the gold standard for metallic biomaterials in modern healthcare. As a low-carbon variant of 316 stainless steel, its unique composition—chromium (16-18%), nickel (10-14%), and molybdenum (2-3%)—enables unparalleled performance in medical environments. Precision-processed 316L components now underpin critical applications from surgical tools to life-sustaining implants, driven by three core imperatives: biocompatibility, sterilizability, and structural integrity.

2. Metallurgical Superiority: Why 316L Dominates Medical Applications

2.1 Corrosion Resistance: The Foundation of Safety

The synergistic effect of molybdenum and chromium forms a robust passive oxide layer (Cr₂O₃) that resists:

- Chloride-induced pitting in physiological fluids (blood, saline)

- Electrochemical corrosion during sterilization with autoclaves (steam at 121°C) or chemical disinfectants

- Galvanic corrosion in multi-material implants

Critical Advantage: 316L exhibits 50% lower corrosion rates than 304 stainless steel in saline environments, preventing ion leaching (Ni, Cr) that could trigger inflammatory responses.

2.2 Biocompatibility: Cellular Acceptance

316L’s non-toxic surface:

- Minimizes protein adsorption and platelet activation, reducing thrombosis risk in vascular devices

- Supports fibroblast adhesion for soft-tissue integration

- Meets ISO 5832/ISO 10993 biocompatibility standards for long-term implantation

2.3 Mechanical Performance

Precision cold-rolling and grinding achieve tailored properties:

Property | Value Range | Medical Significance |

|---|---|---|

Tensile Strength | 515–620 MPa | Withstands orthopedic loading (e.g., hip joints) |

Yield Strength | ≥205 MPa | Prevents permanent deformation in bone screws |

Hardness (HV) | 140–180 (Annealed) | Optimized for machinability & wear resistance |

Elongation | ≥40% | Enables complex shaping of devices |

3. Precision Manufacturing: From Raw Alloy to Medical-Grade Components

3.1 Controlled Processing Protocols

- Low-Carbon Chemistry (≤0.03% C): Prevents chromium carbide precipitation during welding, eliminating sensitization and intergranular corrosion

- Surface Finishing:

- Mirror Polishing (Ra <0.2 μm): Reduces bacterial adhesion sites by 70% vs. rough surfaces

- Electropolishing: Enhances passive layer density, improving corrosion resistance 3x

- Dimensional Precision: Laser-cut plates maintain ±0.005 mm tolerances for implant fit

3.2 Joining Technologies

- TIG/Laser Welding: Minimizes heat-affected zones (HAZ), preserving microstructure

- Non-Destructive Testing (NDT): X-ray inspection ensures weld integrity in gas pipelines

4. Critical Medical Applications

4.1 Surgical & Diagnostic Instruments

- Scalpels/Forceps: Retain sharp edges through 500+ autoclave cycles

- Endoscopes/Catheters: Molybdenum enhances flexibility in articulated components

- MRI Compatibility: Non-magnetic nature prevents imaging artifacts

4.2 Implantable Devices

Implant Type | 316L Component | Performance Advantage |

|---|---|---|

Orthopedic | Bone plates/screws | High fatigue strength (>400 MPa for 10⁷ cycles) |

Cardiovascular | Stents, heart valve frames | Resistance to pulsatile blood flow erosion |

Dental | Crowns, orthodontic wires | Stability in oral pH 4.0–8.5 |

4.3 Hospital Infrastructure

- Medical Gas Systems: Seamless pipes ensure O₂/N₂O delivery without contamination

- Sterilization Equipment: Autoclave chambers withstand 134°C steam at 3 bar pressure

- Hospital Beds/Surgical Tables: Load-bearing capacity >500 kg with easy disinfectability

5. Comparative Advantages Over Competing Materials

Performance Benchmarking

Material | Corrosion Resistance | Biocompatibility | MRI Safety | Cost Efficiency |

|---|---|---|---|---|

316L Stainless | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

Titanium Alloys | ★★★★★ | ★★★★★ | ★★★★★ | ★☆☆☆☆ |

Cobalt-Chrome | ★★★★☆ | ★★★☆☆ | ☆☆☆☆☆ | ★★☆☆☆ |

Polymer Composites | ★★☆☆☆ | ★★★★☆ | ★★★★★ | ★★★★☆ |

Key Insights:

- 316L provides 90% of titanium’s corrosion resistance at 40% lower cost

- Outperforms cobalt-chrome in ductility and manufacturability for thin-wall devices

6. Innovations and Future Directions

- Nano-Engineered Surfaces: Hydroxyapatite coatings enhance osseointegration for orthopedic implants

- Antimicrobial Modifications: Silver-ion impregnation reduces S. aureus colonization by 99.8%

- 3D Printing: Laser powder-bed fusion enables patient-specific implants with controlled porosity

7. Regulatory and Sustainability Impact

- ASTM F138/F139 Compliance: Guarantees chemical/mechanical consistency for implantables

- Lifecycle Advantages: 30+ year service life in infrastructure reduces replacement waste

- Recyclability: >90% scrap reuse rate in production minimizes environmental footprint

Conclusion: The Indispensable Material for Modern Medicine

316L precision stainless steel remains the cornerstone of medical device engineering due to its unmatched synergy of:

- Biological safety (minimal ion release, non-allergenic)

- Mechanical resilience (fatigue/corrosion resistance)

- Manufacturing versatility (precision machining, welding, finishing)

As medical technology advances toward personalized and minimally invasive solutions, 316L continues to evolve through surface engineering and additive manufacturing—solidifying its role as the material of choice where human life depends on metallic reliability.